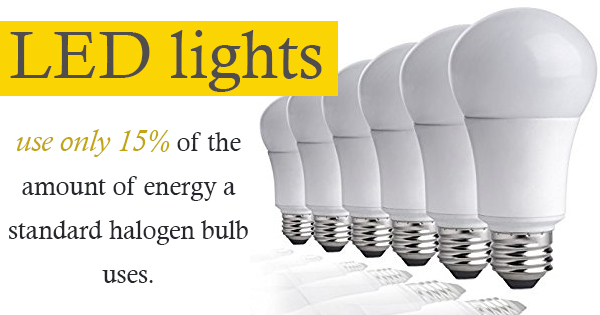

The LED market is arguably the fastest growing in the electronic sector. These lights are being used for all sorts of applications — and for good reason. Of course, LED lights are more energy efficient, which means they’re both practical and eco-friendly. They use only 15% of the amount of energy a standard halogen bulb uses while providing up to 85% greater light output. Thus, they’re incredibly appealing across a plethora of industries and have found their way into everything from sports stadiums to marine environments — and of course, your home.

But although we now rely on LED lights for countless uses, this technology isn’t totally foolproof. It needs to be protected to ensure the lights (and the devices in which they’re housed) work properly. That’s a tall order, considering the harsh environments that LED lights are often subjected to. Harsh temperature conditions, water and excess moisture, and even animal activity have the power to corrupt an LED system. Encapsulation, therefore, is essential. If a business fails to use the right kind of dispensing solutions to protect their LED components, an entire fleet of devices could be jeopardized. If technological performance is somehow corrupted, the ramifications might be substantial.

The addition of any unintended element could spell disaster for technology. Not only could the LEDs be compromised, but other components (such as printed circuit boards or wiring) could also fail. That’s why organizations turn to metered liquid dispensers to protect LEDs and other components with resins such as epoxy, silicone, and polyurethane. Such encapsulation resins lend themselves well to harsh environments. When epoxy resins are administered through a machine’s dispense valves, this often provides some of the toughest protection for LEDs and other electrical components available. While it’s not always appropriate to use a metered liquid dispenser to administer epoxy resin protection in every situation, companies that create products containing LEDs that are exposed to difficult conditions will often consider this option first. The operating environment and materials used are both considered to arrive at the appropriate encapsulation choice.

When creating products that contain LEDs, it’s vital to protect these components from environmental concerns like water, salt, debris, and extreme temperatures. By utilizing a metered liquid dispenser to discharge encapsulation resins, you can maintain the quality and integrity of a given product regardless of operating conditions.