Solutions Consultation Center

EXACT Dispensing Systems takes a solutions-oriented approach in developing the right dispensing system that meets customer requirements. Working in the early process development stages, we provide preliminary consultation in developing the scope of work that identifies the process parameters, fluid properties, budgets and other project requirements that define an application.

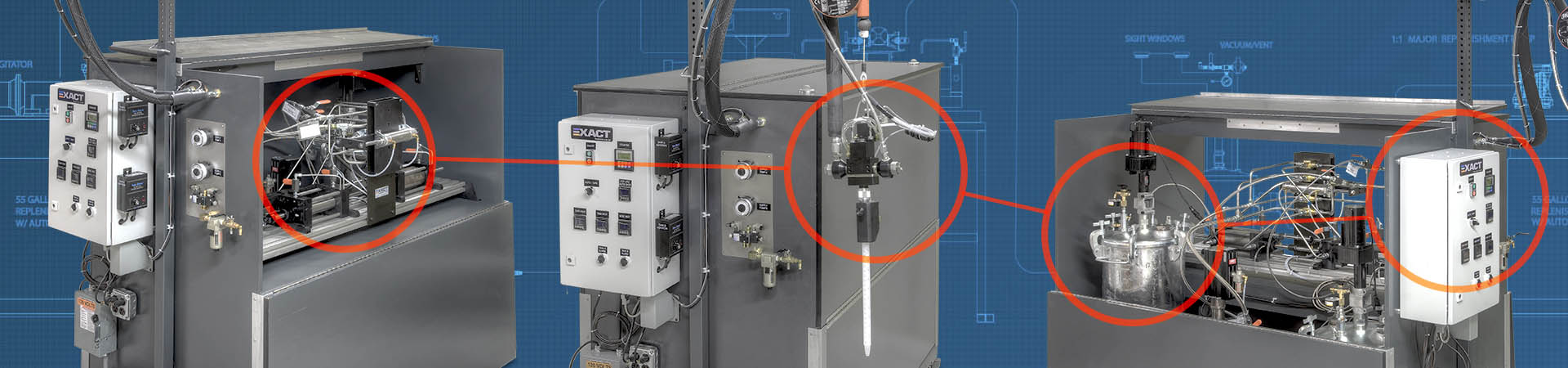

Understanding that no two dispensing solutions are alike even for the same client, our Solution Consultation evaluates the needs of an application to develop a solution based on a customer’s chosen material and requirements. We take into consideration every element including the need for specific types of tanks and pumps, automation, vacuum encapsulation, heated chambers, hand-operated triggers, lift systems for drums and other specifications. Our goal is developing a customized equipment solution that can seamlessly enter into production.

With more than 40 years of experience working with formulators and their different chemistry types, we understand how certain chemistries react to process and environmental factors to provide insights on developing the rights solutions for various applications using resins and adhesives. We save time and money by ensuring customers get the right dispensing solution based on a predetermined set of requirements that is demonstrated in a final wet test acceptance before final delivery.

EXACT globally supports a broad range of industries and processes including electric vehicles, solar, electronics, sensors, filters and an almost infinitely variable scope of products and processes. In addition to the primary focus on potting and encapsulation, we also extend our service to applications requiring precision bead dispensing and a host of other unique single and plural component needs and issues.

Combining our contract services with our product technology, you get more upfront value in specifying new dispensing systems or troubleshooting existing ones.

View Our Solutions

Our Solutions:

Meter/Mix Dispense:

We have over 40 years of experience developing Meter/Mix solutions for volumetric mix ratios of 1:1 to 10:1 and any ratio in between. Inline piston metering, pneumatic or servo driven options as well as gear metering are some of the technologies we utilize to provide you the appropriate solution for your application.

Precision Bead Dispensing:

If you require good bead control in automated production, utilize the new BeadMaster servo drive single or plural component metering solution. This high performance system is ideal for managing bead profile and dispense volumes for low to medium viscosity adhesives or sealants.

Vacuum Dispense:

For the highest quality, air-free results utilize the EXACT vacuum dispense VC solution that dispenses within a vacuum environment to eliminate entrapped air and humidity.

Consider our new High Density, programmable version that increases part load density within the vacuum chamber by 25%.

9450 “Big Shot” Double-Acting 2k

Constant 2k flow with inline Double-Acting Piston Displacement Metering.

Multiple liter pours benefit from large 3600cc cycles @ .5- 50cc/sec.

Many small 10cc shots possible from 6” stroke length.

Inline fixed ratio cylinder set is ideal to ratio thick with thin combinations.

Upstream pumps provide pressure, 9450DA assures precise, constant ratio.

Temperature Conditioning:

Heat applied to the resins during the meter mix dispense process reduces resin viscosity allowing easier fill performance.

Simply providing independent heat zones leaves “cool” circuits that cause variation in viscosities, flow, pressure and possibly ratio.

EXACT’s Hot Box Solution heats the entire system offering the best in fluid control.

Automated Fill:

Filling of containers, molds and cavities can be optimized by using an EXACT Optical Fill Sensor (OFS) Solution that views the level of dispensed single or plural component resin in the cavity. These solutions are ideal when the required volume to fill the space is variable or unknown.

XY-D Automation:

These solutions offer both XY motion platform control and dispense control in a single integrated solution providing easy start-up and operation.

Customized Systems:

We can design and build a complete system customized to your needs and requirements