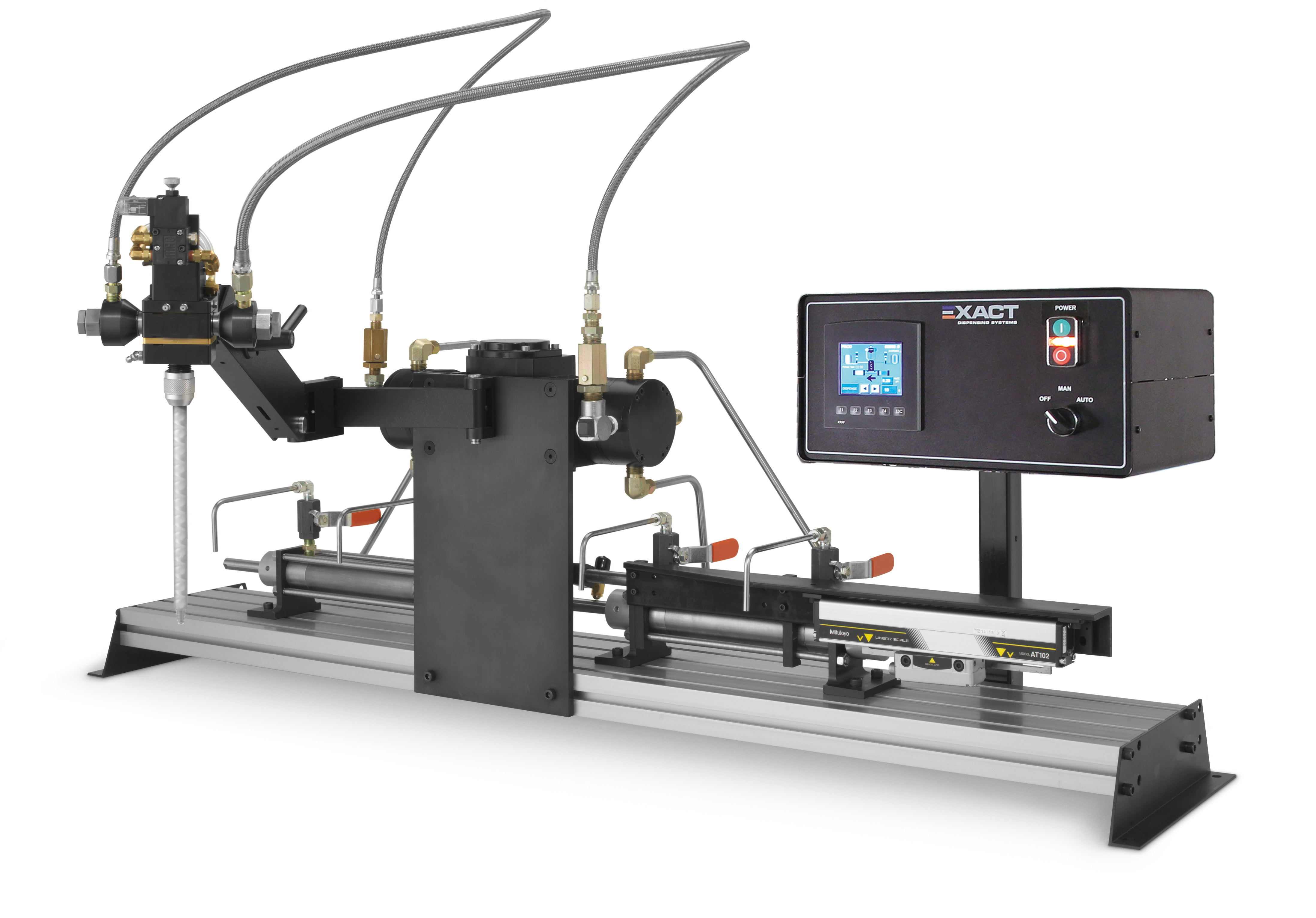

Model 1450 Double Acting Dispensing System

Designed for intermittent/continuous dispensing of two component epoxies, urethanes, silicones, polysulfides and others.

Specifications

Bore (Major Component): 1.500" diameter

Stroke: 5"

Full Stroke Volume (1:1 ratio): 8 fl. oz/239 cc

Overall Length (Baseplate): 53"

Overall Length (with Encoder): 55"

Features

- Wide range of bore sizes and ratios to satisfy your production requirements.

- Positive displacement piston metering for consistent, accurate delivery of A and B materials. Ratio is assured by honed cylinder diameters.

- Precision Linked Diverting Valves (LDV) eliminate problems caused by unreliable check valves.

- Low cycle rate for improved wear. Multiple process shots per stroke.

- Stainless steel, PTFE, hard coated nickel and Cryogenically treated components ensure long lasting performance, even with abrasive materials.

- Manual ("eyeball") or precise volumetrically controlled dispensing.

- Mixer manifold isolates materials until they enter the disposable mixer.

- Inexpensive disposable mixing. No solvents.

- Material is pressure fed from tanks or pump fed from 5 gallon pails, 55 gallon drums, or other bulk containers.

Encoder: For critical applications requiring precise shot size. Accuracy to .0008" of cylinder stroke. (.0004" optional)

Pumps: Wide range available for use with 5 gallon to 55 gallon containers. Air assisted ram for heavy or viscous liquids.

Heated hoses: Up to 20 feet.

Tanks:

Vacuum Conditioning

1 Quart to 30 gallons

Digital or "Dial set" heat

Agitation-pneumatic or electric

Nitrogen blanket for moisture sensitive materials

Level controls

Sight "View" Windows

Systems Integration: Interfacing of EXACT dispensing equipment with your process.

Portable skids/carts: Engineered for your application and process, offers mobility for remote task requirements.