Epoxy Use in the Fiber Optic Cable Assembly Process: FAQs

Epoxy dispensers are used to create materials used in countless applications. The assembly and manufacturing of fiber optic cables, for example, is a process that relies on adhesive dispensing solutions to make a superior product. But working with epoxy dispensing solutions is not always a foolproof technique. Whether you’re having troubleshooting issues or simply want to learn more about the frequently asked questions and pitfalls manufacturers face, you’ll want to keep reading.

Epoxy dispensers are used to create materials used in countless applications. The assembly and manufacturing of fiber optic cables, for example, is a process that relies on adhesive dispensing solutions to make a superior product. But working with epoxy dispensing solutions is not always a foolproof technique. Whether you’re having troubleshooting issues or simply want to learn more about the frequently asked questions and pitfalls manufacturers face, you’ll want to keep reading.

Will over-mixing epoxy really make a noticeable difference?

Epoxy dispensers can take a lot of the guesswork out of this process — but it’s an EXACT procedure (pun intended). Mixing an epoxy to excess before dispensing can cause air to become trapped in the material. This produces bubbles, which can compromise the integrity of the epoxy itself. When mixing different components for your epoxy, you’ll need to make efforts to minimize bubbles. It helps if you use a consistent mixing technique and take care to mix adequately, but not too much.

What are some ways to improve the quality of an epoxy work station?

Since the quality of your epoxy can be unintentionally altered using an unclean surface, you’ll need to plan ahead and maximize efforts to keep all materials in their intended state. Make sure your equipment, tools, and containers have been rinsed with electronic-grade isopropyl alcohol and invest in a professional epoxy dispenser to ensure everything is positioned and dispensed as intended. You may also want to consider using a polyethylene work surface, as it’s chemically resistant and extremely easy to clean.

EXACT uses isopropyl alcohol as a primary “go to” for many of our cleaning requirements. It’s important to ensure that it is dry before introducing any reactive chemistry. Alcohol is hygroscopic (absorbs moisture). It also can drastically change the surface temperature of a substrate during evaporation. Temperature changes change cause condensation. Hence, drying is critical as many formulations are moisture sensitive.

Does it matter if epoxy cures differently every time?

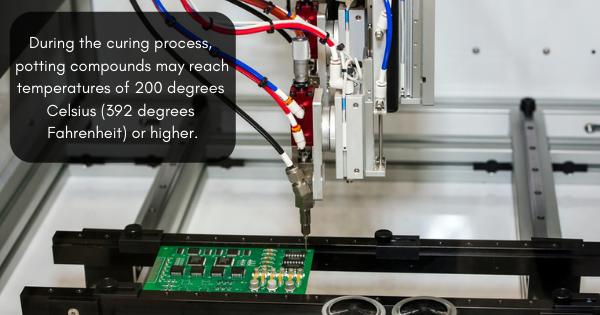

Slight color changes may not be anything to worry about, since raw materials may have tiny variations that sometimes affect the hue of the epoxy. But other than that, you should be concerned with differences in how the epoxy cures. Typically, this won’t be due to faulty epoxy (though that can occur in rare cases). More often, a curing discrepancy occurs when there’s been some variation in how the curing has been performed. During the curing process, potting compounds can reach 200 degrees Celsius or higher. If you find that your epoxy is taking longer than usual to cure, you can raise the temperature. But keep in mind that consistency is key; if you’re experiencing these issues for the first time, you may want to take a closer look at the materials being used or the epoxy dispenser itself to discern whether there’s another problem at play.

If you need better adhesive dispensing systems for your fiber optic cable assembling and manufacturing, we’re here to help. To learn more, please contact us today.