When a part is made using dispensing solutions, it may need to be altered later on. Trying to manually add parts or layers of material can be time consuming and challenging. Fortunately, overmolding allows users to add additional layers of silicone or epoxy material to create a flawless part. Let’s delve a bit deeper into the overmolding process.

What Exactly Is Overmolding?

At the most basic level, the overmolding process allows for a base part to be completely or partially covered by another material. The main part is manufactured first, and for this example, let’s assume the part is a watertight electrical connector. Of course, in order to make the connector watertight, an additional substance will need to be molded to the base part. Some type of dispensing machine is used to mold plastic resins, epoxies, urethanes, silicones, polysulfides, or some other type of material to the connector. Thus, the electrical connector will eventually become part of a fused whole.

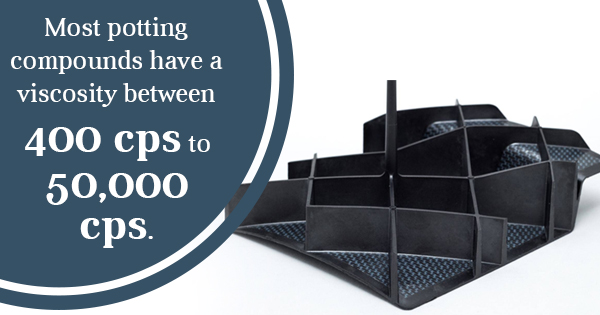

Overmold materials are heated and melted by the dispensing machine so they can be injected onto the part. During the overmolding process, the encapsulation compounds must flow evenly in order to fully cover the electrical components or other parts without creating air bubbles or voids. Most potting compounds have a viscosity between 400 cps to 50,000 cps, which is a crucial element of achieving a smooth overmold. Overmolding is used in a variety of fields to create tons of different products such as cables, cable end seals, printed circuitry components, and other electrical parts.

Applications of Overmolding

Overmolding is used to create a variety of products, including products people use every day. Some common forms of overmolding can include:

- Epoxy over metal

- Silicone over metal

- Plastic over plastic

- Plastic over metal

- Rubber over plastic

- Rubber over metal

This process can be used to add texture, color, or a functional aspects to a product. The possibilities with overmolding machines are almost endless, and this process can improve both the design and functionality of a part.

When overmolding is used, the manufacturing process can be streamlined with ease. Instead of depending on rings, sealing fixtures, and other elements to fuse two parts together, the sealed part of a finish product is simply part of the product. Without overmolding, manufacturers will be using more epoxy dispenser materials and parts than necessary to get the job done. With high quality dispensing machines, overmolding is a highly efficient process that can can save companies time and money.

As you can see, overmolding can bring about a streamlined process in any manufacturing business.