4 Top Tips For Preventing Adhesive Dispensing Clogs

Adhesive dispensing systems are undoubtedly useful, but it’s absolutely essential to use them properly to avoid potential problems. One of the most common issues businesses report regarding their customized adhesive dispensing machines is clogs. Clogs and spills can occur quite frequently if the right steps aren’t taken to prevent them. Here are just a few ways to avoid clogs and other issues within your adhesive dispensing systems.

Use Plastic Tips

Adhesive dispensing solution tips come in many materials, shapes, and sizes, but experts say plastic is ideal for preventing clogs within the tip of the system. If you’re unsure which specific type of plastic is best for your unit, consult the manufacturer’s manual or opt for polypropylene or polyethylene for best results. Similarly, never use a metal tip when dispensing an anaerobic adhesive. Go to the meter mix dispense machine builder for the correct tips as well as they are vitally interested in your success.

Opt For Opacity

Some adhesives are UV curable, and if yours is, it’s best to ensure that the dispenser tip has the ability to block the light. Fortunately, in this case, it doesn’t make much of a difference whether the tip is plastic or metal.

Reduce Idle Time

If you’re using an instant adhesive, you should be aware that they may be more likely to clog when left unattended or are improperly maintained. With this in mind, it’s best to remove the tips and place them in the proper solvent prior to taking a break or ending the work day.

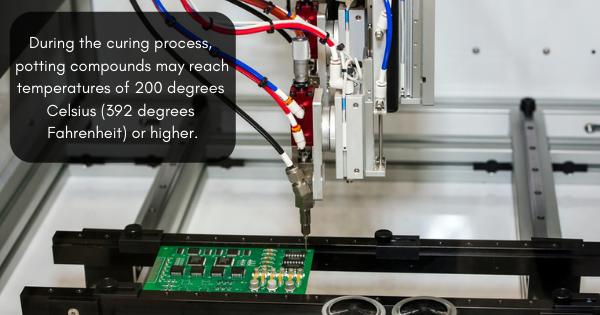

Heat Tips Slowly

Centipoises is a unit of viscosity (with water as the standard = 1.0) for indicating the fluidity or flow property of a liquid at room temperature. As with many other substances, many types of adhesives tend to harden and clog at lower temperatures. This is especially the case with single part epoxies, which will only cure with heat. To prevent or remove clogs within a single part epoxy dispensing system, heat the tips to a temperature that’s just above room temperature. If you’re still uncertain, it’s best to consult the experts at EXACT.

Ultimately, understanding how to effectively prevent and solve any and all adhesive dispensing clogs is the key to ensuring maximum lifespan, quality, and efficiency. For more information about dispensing solutions, contact EXACT Dispensing Systems.