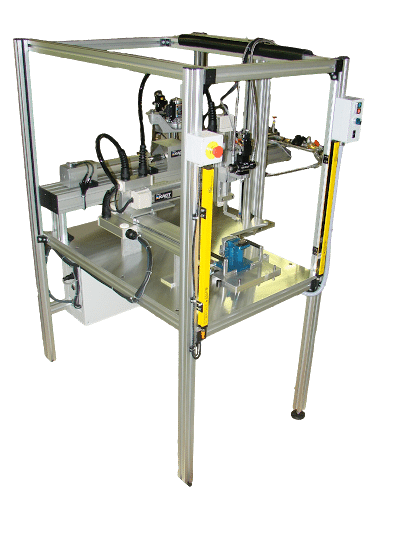

Beadmaster Bead Dispenser

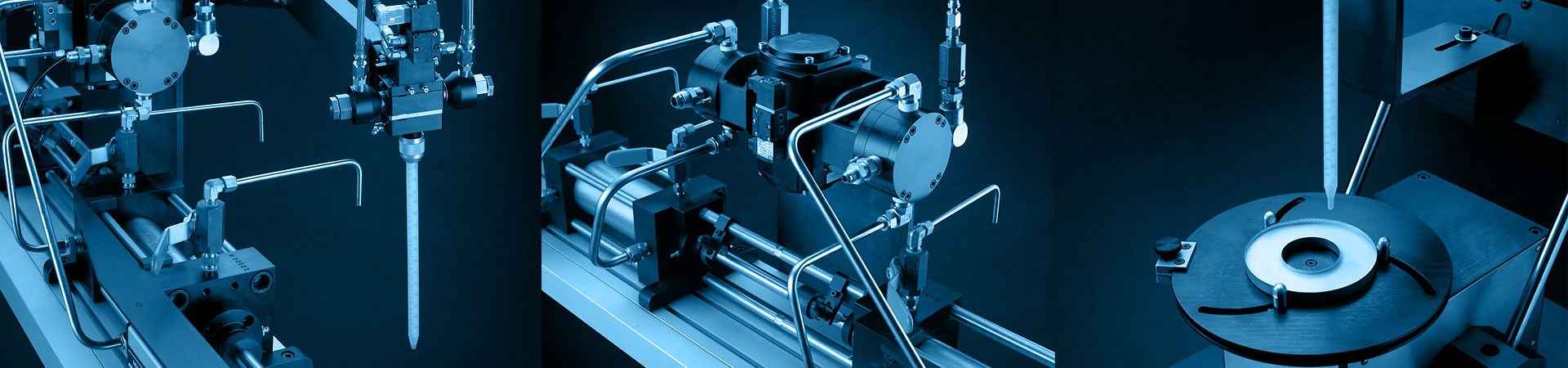

Servo driven volumetric dispense systems for flow rate sensitive applications of viscous single or two component formulations. The Beadmaster is an ideal meter to supply on ratio, metered volume and at the required rate in response to system requirements.

Features:

- Compatible with self-leveling and Paste Formulations

- Dispense valve selected for the application

- Suitable for filled materials

- Digitally controlled flow rate

- Multiple Incremental shots from large positive volumetric displacement unit

- Incremental dispense technology extends service and minimizes wear

- Linear servo Metering ensures accurate ratio and consistent flow rate

- Stainless steel, cryogenically treated tool steel and hard coated nickel components ensure long lasting performance with abrasive materials

- Seals available for most all chemistry

Models

BeadMaster Model 1450 Single (One component resin)

Specifications:

- Up to 145cc/5" stroke

- Typical dispense volumes 1 to 5 cc

- Accuracy ±1%

- "Blind Rod" metering design available

- 200 to 1000 psi typical application pressure

- Control options suit most applications

- Complete EIC (EXACT Integrated Control) XY-D systems provide XY Motion and Dispense controlled in one controller available

BeadMaster Model 1450 Double (Two component resin)

Specifications:

- Up to 265 cc per 5" stroke

- 5' diameter, 145 cc, major cylinder capacity

- Custom ratios up to 10:1

- Positive displacement piston metering for consistent, accurate delivery of A and B materials

- Linear Metering Cylinder set eliminates racking associated with other designs

- Complete EIC (EXACT Integrated Control) XY-D systems provide XY Motion and Dispense controlled in one controller available